What Is Electricity Fuse? How Does It Work? Why Does It Blow?

What is in this article?

Excessive current flowing through an electrical circuit can damage appliances and even cause fires, threatening human life. For this reason, it is necessary to use fuses to protect against anything that goes wrong where electricity is used.

You can find everything you wonder about the working principle and types of electrical fuses in our article.

What Is Electricity Fuse?

Electrical fuse is a part that eliminates potential hazards such as excessive temperatures, short circuits and power surges in electrical systems, protecting the supply lines and at the same time protecting the people using the fuse against possible accidents.

Electrical fuse is a part that eliminates potential hazards such as excessive temperatures, short circuits and power surges in electrical systems, protecting the supply lines and at the same time protecting the people using the fuse against possible accidents.

Fuses are usually rated in Amperes. The functionality of the tools can vary depending on their self-generation of heat through their own developed electrical resistance. This can usually be achieved by keeping the fuse wire length as short as possible. However, the wire length does not depend on the available rating values; the minimum wire length imposes the minimum resistance value.

Fuses connected in series with the circuit are deliberately placed at a weak point in the circuit. This ensures that when high current flows through the circuit due to overload or short circuit, the circuit opens as specified by the standards. In this way, the circuit is protected from the possible dangers of overcurrent.

The electrical fuse box is a metal box at the center of the electrical system where the incoming voltage is divided into various circuits. It is also called the main panel, switch board or circuit board. It provides power to all electrical systems in homes and workplaces.

-

What Is an Electric Fuse Used For?

After the widespread use of electricity, electric fuse was invented by Thomas Alva Edison in 1890. Although many types of fuses have been developed since then, they all have the same function.

Fuses have functions such as preventing ignition and breakage of wires, limiting current flow, terminating the current in case of overload or short circuit, and protecting devices against power outages.

Fuses are used to prevent faults in electrical installations and to prevent household appliances from being damaged by high current. When a fuse blows or is damaged, a sudden spark is produced that can directly damage household appliances. There are many different types of fuses to protect appliances against the risk of fire and similar overload damage.

-

How Does an Electric Fuse Work?

Fuses consist of a metallic, low-resistance wire encased in a fire-resistant material. They are used in series with a circuit or device that needs to be protected from short circuit and overcurrent.

Fuses consist of a metallic, low-resistance wire encased in a fire-resistant material. They are used in series with a circuit or device that needs to be protected from short circuit and overcurrent.

Otherwise, in the absence of fuses and circuit breakers, electrical devices may be damaged because they cannot withstand the electric current.

The working principle of a fuse is based on the heat effect of electric current. When a short circuit, overcurrent or mismatched connection occurs, the thin wire inside the fuse melts due to the heat generated by the heavy current passing through it and prevents feeding.

It therefore disconnects the power supply from the circuit. When the circuit is operating, the fuse wire is only a very low resistance component and does not affect the normal operation of the system connected to the power supply.

In the event of a fault, a short circuit current is generated in the devices. This current is greater than the current in a normally operating circuit. This means that the fuse box is overheating. The fuse provides protection against factors such as short circuit and overcurrent.

What Happens if an Electric Fuse Is Not Used?

Fuse is a means of protecting electrical circuits against short circuits and overloading of circuits. It consists of a metal wire or thin strip of metal with a low melting point that is inserted into the electrical circuit as a protective device.

If this element is not used, electrically powered devices may draw current above normal values. Highly heated devices may malfunction or burn out. At the same time, there is a risk of electric shock to people who come into contact with devices that are overloaded with excessive current.

Why Does an Electric Fuse Blow?

A common cause of a fuse blowing is too many lighting fixtures or plug-in devices drawing power from the circuit. These devices can overwhelm the capacity of the fuse and melt or damage the wires inside the box. As a result, all lamps, outlets, and appliances drawing power from the circuit will stop working. In this case, the fuse must be replaced with one of the same rating.

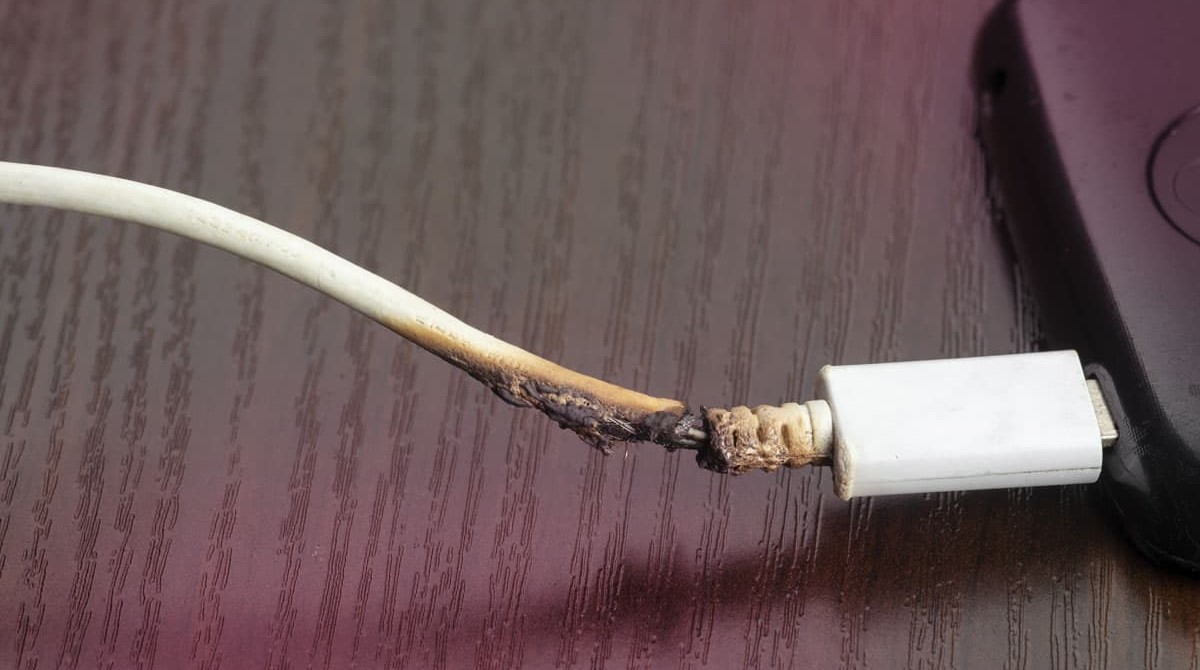

Another cause is a hot wire somewhere in the system touching the ground or a neutral wire. This is also called a short circuit and is caused by loose wire connections, wiring damage somewhere in the circuit, or an internal wiring problem in a device connected to the circuit.

This can be illustrated with a lamp. A lamp with improperly connected wires will blow a fuse or cause a short circuit when plugged into a socket. Rodent-damaged or broken wires can cause a hot wire to touch ground or neutral.

In these cases, the first symptom is the same as for an overload. The metal strip inside the fuse lights up and all lights in the circuit go out. However, replacing the fuse may not be a solution if the short circuit is not removed. The same problem may occur when the new fuse is connected to the circuit.

The location of the short circuit can be difficult to diagnose. Since there are many short circuits in pluggable lamps or appliances, it is necessary to unplug each lamp and appliance and then replace the blown fuse. If the new fuse does not blow, the problem is probably in the unplugged lamps or devices. Otherwise, the problem is in the wiring itself.

-

How Can You Prevent a Blown Electrical Fuse?

To prevent fuses from blowing, the first step is to prevent overloading. To this end, it is a good idea to move some plug-in devices used in homes and workplaces to other circuits.

To prevent fuses from blowing, the first step is to prevent overloading. To this end, it is a good idea to move some plug-in devices used in homes and workplaces to other circuits.

Household appliances such as toasters, vacuum cleaners or irons are prone to overloads, especially when they are first put into operation, as their power consumption is quite high. To avoid this, products should not be plugged in at the same time, or different sockets should be used.

For this purpose, the total power consumption of the electrical devices can be calculated. The peak power of the products must also be taken into account in the calculation. It is also useful to calculate how many amps each circuit can handle without overloading.

Care can also be taken when using extension cords to ensure that the fuse does not blow. Although extension cords provide temporary relief to the circuit, they may not be an effective solution in the long run. Therefore, limiting their use is one of the most effective methods.

It is common for fuses to blow due to damage to the cords. Electrical inspection, which should be done at least once a year to determine if there is a problem in the wiring, should not be skipped.

Types of Electrical Fuses

Electrical fuses are basically divided into AC and DC fuses.

Regardless of whether they are AC or DC, automatic fuses are now generally used for safety purposes. Overload protection in automatic fuses is provided by a magnetic circuit breaker against short circuit and a thermal circuit breaker against overload. The circuit breaker can be easily reset after an interruption. For this reason, fuses are increasingly being replaced by automatic circuit breakers.

A.AC Fuses

AC fuses oscillate approximately 50-60 times per second. This is the current that flows through the fuse circuit in a given time. Since there is no arcing between the fusible wires, these models are very small.

AC fuses are divided into high voltage and low voltage fuses.

A.1. High Voltage Fuses

High-voltage fuses used in power transmission lines are designed to protect the circuit from short circuits and leakage faults caused by overvoltage and load, damage to conductive parts, lightning strikes, and so on.

These types of fuses are divided into two types: impact pin and optical indicator:

Impact pin fuses, a pin is released when the fuse blows in fuses with an impact pin. This pin both recognizes that the fuse has blown and activates a mechanical part with the energy it releases.

Fuses with optical indicator, high-voltage fuses with optical indicators provide information about the status of the fuse thanks to the indicator on the fuse. When the fuse blows, a red thimble appears on the indicator, making it easier to find the damaged fuse.

A.2. Low Voltage Fuses

Low voltage fuses are fuses with a voltage rating of 1,500 V or less. They are divided into groups as they are produced with different features and technologies:

A.2.1.Cartridge Type Fuses

Cartridge fuses are placed in tightly sealed containers with a metal contact point at both ends. The completely closed structure ensures that the arc remains in the container when the fuse blows. Although known as low voltage fuses, they are also found among high voltage fuses.

These fuses are categorized as D type and connection type:

A.2.1.1.D Type Fuses

These fuses consist of a cartridge, fuse base, cap and adapter ring. The cartridge is inserted into the fuse cap while the adapter ring is inserted into the fuse base. The end of the cartridge must contact the conductive parts to complete the connection.

A.2.1.2.Connection Type Fuses

Connection type fuses are designed to interrupt high current. The body of the fuse is usually made of porcelain or ceramic in order to control the arc in case the fuse blows.

These fuses are divided into two as blade and bushing type:

Bladed fuses are used to interrupt the current reaching high values. They can be used in place of screw-in plug-in fuses, especially those rated greater than 100 Amperes. In automotive electrical applications, the majority of fuses are blade type fuses that fit into a small plug and are made with two prongs.

In these fuses, the ampere rating, i.e. the maximum current the fuse can carry, is indicated on the top of the body. The amount of electricity passing through the circuit can be measured in this way.

Cartridge Fuse consisting of a porcelain or glass body and cover, these fuses are equipped with siliconized sand or conductive wires to protect against high currents. Conductive wires are used together with wires that will resist when there is more current than normal. The two ends of the body are kept long to prevent electric arcing. Since it is specially designed according to the area of use, it can be used both in homes and businesses.

The cartridge which gives the fuse its name, is the part with the wires that melt when the fuse blows. Since it is designed for certain current values, it is responsible for opening the circuit by melting when high current passes through it. In order for the circuit to work again after the circuit is interrupted, the fuse must be replaced.

A.2.2.Rewindable Fuses

It consists of a base and fuse carrier containing the rewindable input and output terminal. The base is usually made of porcelain and contains copper or aluminum parts. The fuse carrier is mounted on the base. If the fuse is damaged by overcurrent, it can be removed without risk of electric shock. This makes it easy to replace the wires.

Although these fuses are most commonly used in households, they are also used in small industrial plants and other low-current applications.

A.2.3. Switch Fuses

Switch fuses provide protection against magnetic and thermal effects. It has the advantage of being a single part and can be used as a switch.

A.2.4. Drop-Out Fuses

Dropout fuses, which provide protection against short circuits and are used in switching operations, are widely used with 10 kVA electrical distribution transformers. These fuses, used as circuit breakers, create a safe working environment for the line and equipment.

B.DC Fuses

DC fuses have a constant value just above 0 V. This makes it difficult to close the circuit and can cause arcing between the fused wires.

To avoid this, the electrodes are placed at a greater distance from the fuse. DC fuses are therefore larger in size.

Have you had similar experiences with the very common situation of a blown electrical fuse? You can tell us about it in the comments.

Online Services

Online Services Application Inquiry

Application Inquiry Pay Assurance Fee

Pay Assurance Fee Query Installation Number

Query Installation Number Compensation Fee Inquiry

Compensation Fee Inquiry Automatic Payment Order Inquiry

Automatic Payment Order Inquiry Partnership

Partnership

Leave a Comment