What is in this article?

Electricity, which is used in almost all aspects of life, can sometimes cause hazards to human life. Various measures are taken to prevent undesirable situations caused by electricity. One of the most effective measures taken for this purpose is grounding.

With the grounding method, all parts of the installation that are not live are connected to another conductor, which is laid in a ground, by selecting suitable conductive materials. This method is used to ensure the safety of people using electrically powered equipment and to prevent damage to the equipment.

Grounding establishes a conductive connection between a part of the operating circuit and the ground. To ensure safe and healthy living conditions, the housings of electrical machines, the metal parts of their leads, the lead sheaths of lead-containing cables, and all metal parts must be grounded.

Read the rest of our article to learn what grounding is, how it is done, and what you need to know about grounding.

What is Grounding?

Grounding is the connection of non-energized metal parts of electrically powered machines to the earth through a conductor. The purpose of this application is to minimize the current that flows through the human body in the event of a fault current such as short circuit that can occur in machines. At the same time, grounding ensures that the protective devices in the circuit also work. Thus, the defective part is quickly deactivated.

In addition to protecting human life, one of the most important benefits of grounding is that it prevents damage to machinery and ensures continuity.

In this way, the excess electric current that may occur in the equipment is transferred to the ground through the ground wire with extremely low resistance, eliminating the risk of damage to the people who touch the equipment.

-

Problems that can Occur If Grounding is not Provided

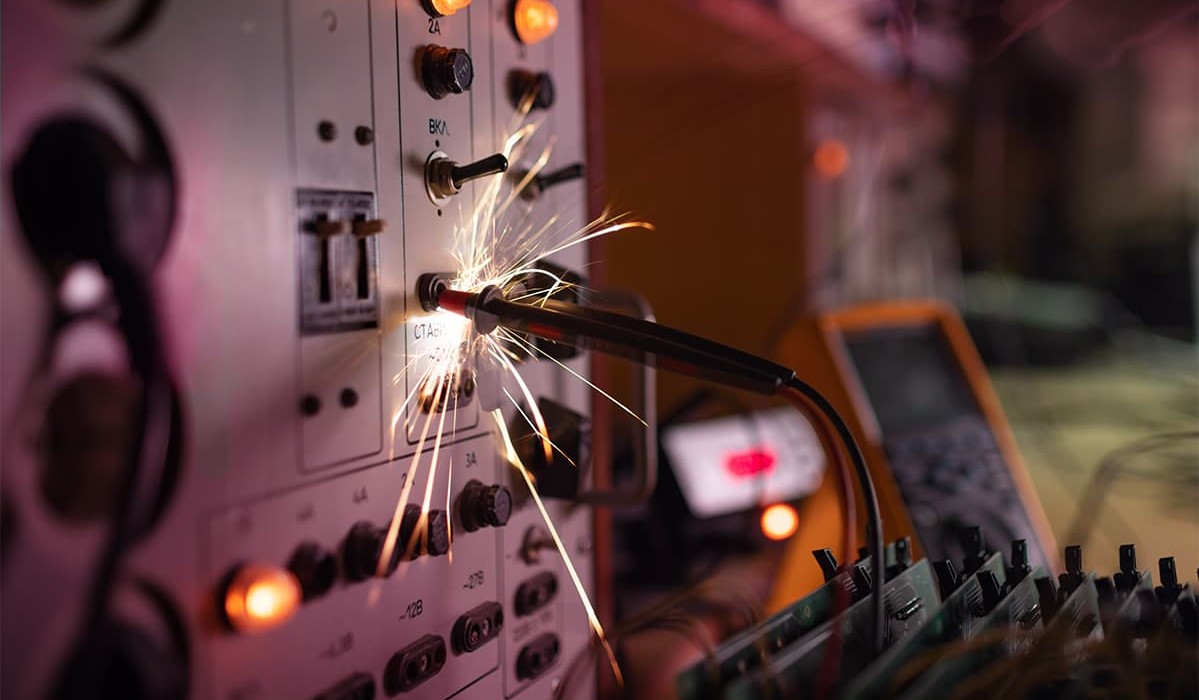

Although electrical power facilitates work in many different areas of life, it can pose a danger to people and other living things if the insulation is not proper. The first of these hazards is electric shock. Electric shock occurs when two different areas of the body have different electrical charges and current flows through them.

Accidents caused by electric shock are divided into three categories in terms of their effects:

- It can affect the nerves, muscles, and heart.

- Heating and arcing can cause burns.

- Various injuries can occur due to falls or impacts from fear.

What are Types of Grounding?

Different types of grounding can be used for different purposes:

-

Protection Grounding

It is to protect people from dangerous touch voltages. The metal parts of the machines in the building that are not live under normal conditions are grounded. For example, the boiler of the washing machine rotates with a motor through which current flows.

Together with the motor, all parts through which current flows are called active parts. Although the boiler and outer body are also conductive, they are also passive parts because no current flows through them under normal conditions. From time to time, undesirable situations may occur and passive parts may become energized. In such a case, there is a vital risk for persons touching these points. To prevent this, protective grounding is performed.

-

Operation Grounding

It is the grounding of the parts of the equipment in a business that are live under normal conditions. The aim of this method is the normal operation of the operating circuit. In normal operation of a grid, the voltage of the neutral point to ground is considered to be zero.

However, if the neutral point is not grounded during a short circuit, undesirable situations will occur with respect to insulation. To prevent this, the neutral point must be grounded. Moreover, thanks to the grounding, one obtains a point with constant potential for the grid. Possible transient over-voltages are also prevented in this way.

-

Function Grounding

It is made so that the control element can perform the desired function in the companies. As examples of function grounding can be mentioned the grounding of the rail system or the grounding for protection against lightning.

For example, the grounding of lightning rods, which are located at the highest points of buildings, falls within this scope.

-

Lightning Protection Grounding

To protect against possible lightning strikes in electrical installations, the grounding ends of surge arresters that protect equipment from high voltage, as well as all metal parts where this possibility exists in outdoor installations, are grounded.

Examples of these parts are the protective conductors of air lines, metal or concrete poles. Lightning protection grounding is actually a type of protective grounding. The purpose of this grounding is to ensure that the high voltage caused by the power outage is passed to the ground without damaging the equipment in a business and the people who use the equipment.

In this way, the lightning that strikes the building is thrown into the ground without endangering human lives and becomes harmless.

Why is Grounding Very Important? What Happens Without Grounding?

All businesses must have a properly designed and regularly maintained grounding system that is monitored by fault currents. Without grounding, material damages may occur and accidents may seriously affect human life. Likewise, a weak grounding can cause great damage.

All businesses must have a properly designed and regularly maintained grounding system that is monitored by fault currents. Without grounding, material damages may occur and accidents may seriously affect human life. Likewise, a weak grounding can cause great damage.

The grounding system aims to establish a conductive connection between certain points of panels, devices and machines and earth electrode.

The earth electrode, also known as the grounding electrode, is buried because it is a conductive part, thus creating an electrical connection with the earth.

Thus, with this conductive connection between the devices and the earth, the device body is grounded and insulation failures that may occur in the devices are prevented.

Thanks to grounding, a possible fault current flows directly to the ground. However, if no grounding is done, the fault current passes directly to the people who touch the malfunctioning device. When grounding is not done properly, the risk of electric shock increases as well as the risk of malfunctioning devices and machines. In addition, equipment may malfunction, unwanted voltage and current changes may occur or power factor problems may occur.

The grounding system conducts the fault current to earth via a conductor. A good grounding system not only ensures safety, but also helps to prevent damage to both the grounding plant and the equipment, as well as fires.

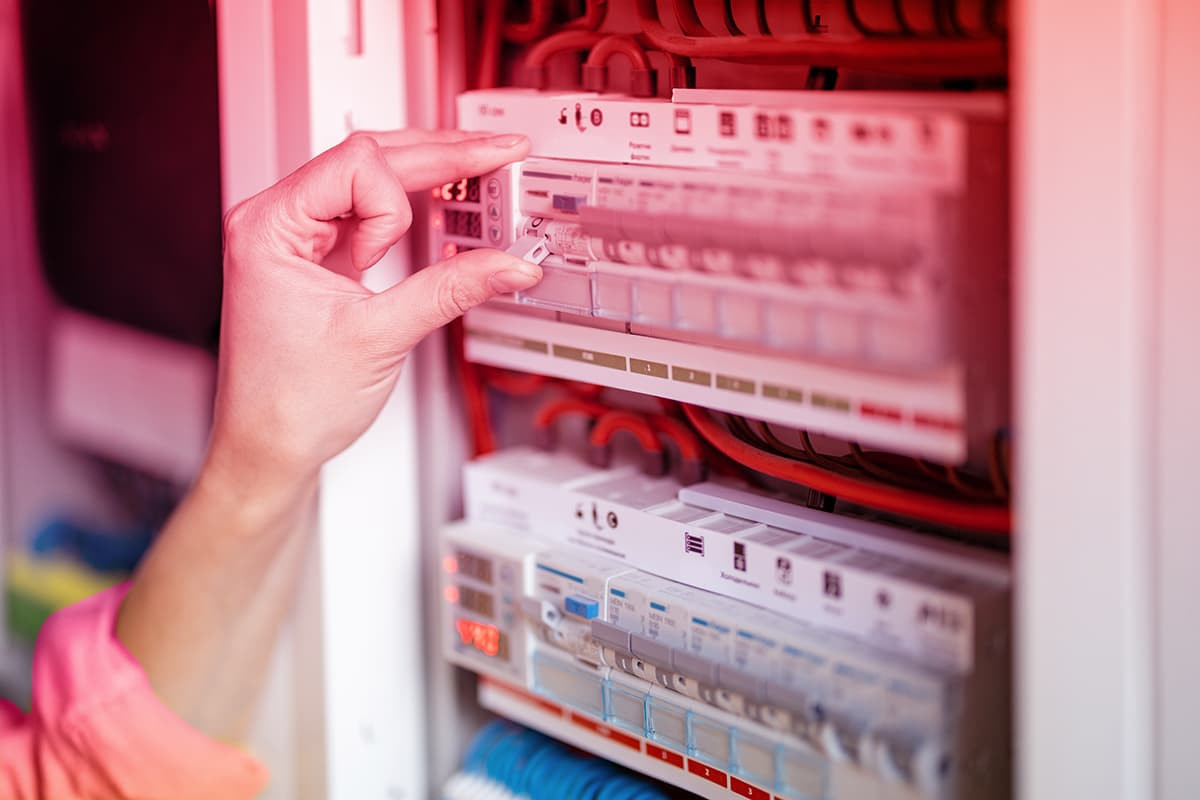

A properly constructed grounding system ensures that leakage currents are safely conducted to earth. In addition, the inclusion of an automatic fuse system allows for the safe disconnection of electricity. The automatic fuse system can be used wherever there is an electrical installation.

This system, which works automatically, provides protection in case of overcurrent or short circuit. In other words, grounding has a serious importance in terms of protecting both human life and devices and investments.

A proper grounding system increases the reliability of the equipment and minimizes damages caused by lightning or fault currents. Electrical fires cause great material damage every year. In addition, work efficiency is reduced as personnel loss may occur.

-

Does Grounding Save Electricity?

Grounding does not save electricity. The electric current required for the operation of the machines is independent of the ground line. Therefore, electricity leaks are not prevented by the ground line. Only the leakage current is transmitted to the ground and safety is ensured.

-

Does Grounding Prevent Electrical Faults?

Grounding helps to prevent many different possible electrical faults. An electrical leakage in one of the devices can cause malfunction and fire in the device, as well as affect other nearby electronic devices. Not only the device where the leakage is observed, but also others may start to malfunction. In such cases, serious consequences can occur.

Grounding minimizes the possibility of such situations. Thanks to this system, many different dangerous situations are prevented, from short circuit to electrical leakage, from sudden contact to electrical faults.

Thus, while many vital and material risks are reduced, the life of the equipment is also extended.

How to Tell If There is Grounding?

It is actually very easy to understand whether there is grounding in homes. With the help of a tester screwdriver, this process can be done in a short time.

It is actually very easy to understand whether there is grounding in homes. With the help of a tester screwdriver, this process can be done in a short time.

You can find out if there is a problem by checking all the sockets in the house with a tester screwdriver. Before starting the procedure, the power must be turned off at the fuse box and insulating gloves must be worn for safety reasons.

Then, the tester screwdriver is inserted into the holes of all the sockets in the house and tested. If the pin lights up even though you turn off the power, you can assume that there is an electrical leak.

How to Ground?

Safety measures must be taken before grounding. These include turning off electrical fuses, having a tester screwdriver ready, and wearing insulating gloves. Stick electrodes are also needed for grounding.

First, take some copper rods with suitable characteristics for the area to be grounded. The cables are well connected to the copper rods. Pits are dug to the required depth on the floor of the building where the grounding is to be done. Then the copper rods, to which the cables are connected, are placed between these pits.

To reduce the resistance of the system, the pit is filled with a special soil mixture. The grounding wires coming from the building are integrated into this system. If there is not already a ground wire in the building, the system is pulled up to each apartment.

-

What Should be the Value for the Grounding Measurement?

The resistance of the ground is expressed in Ohm-meter. Thanks to the measurement, it is possible to obtain information about how the soil conducts electric current. The electrical resistance of a conductor with uniform cross-sectional area and uniform length is called resistivity. The lower the resistivity, the lower the required resistance of the grounding electrode.

The specific resistance of the soil may vary depending on the region and type of soil. This is because moisture and temperature affect resistivity. Weather conditions such as frost and drought increase resistance. Therefore, soil resistivity may also vary depending on the season or time of measurement.

Temperature and humidity values become more stable as they penetrate deeper into the soil. Therefore, to minimize seasonal effects, measurements should be taken at greater depths. For this purpose, the measuring rods should be buried as deep as possible.

Resistance values of grounding systems vary with soil type. In Appendix-K of the Ordinance on Grounding in Electrical Installations, the resistivity values of the different soil types are given as follows:

| Soil Type | Soil Resistivity (ohm inch) |

| Swamp | 5-40 |

| Mud, clay, humus | 20-200 |

| Sand | 200-2500 |

| Pebble | 2000-3000 |

| Rock scattered by weather | Mostly <1000 |

| Sandstone | 2000-3000 |

| Granite | >50000 |

| Ice stone | >30000 |

Grounding measurements provide important information on the selection and positioning of grounding electrodes on large construction sites or in factories.

The following information can be derived from measuring the resistivity of the soil :

- Before the buildings are erected, site location, grounding electrode and grounding type can be selected.

- The technical specifications of the grounding electrode and grounding system can be determined.

- By determining the soil resistance, the cost of the grounding system required for the area can be optimized.

There is no clear information on what parts make up an ideal grounding system and what the resistance value should be. Again, although it is believed that the ideal grounding resistance should be zero ohm value, there is no standard value accepted by all institutions.

Why does the Current Flow into The Ground?

The ground is an ideal place for current to flow because it is positively charged. At the same time, this situation is also triggered by the collision of charged particles in the atmosphere and the resulting filling of the clouds with negatively charged ions.

How Do You Measure the Ground Line at Home?

An avometer, also known as a digital multimeter, is used to measure grounding at home. The control wires of this device are connected to the electrical devices connected to the wall outlet and the measurement is performed. Most often, a computer cable is used for this operation. When the device is measured in resistance mode, the result is given in ohms.

What Is the Ground Resistance?

Ground resistance refers to the value measured between the grounding device and the sufficiently distant reference ground. This value, in short, is the sum of the grounding device's resistance to propagation and the resistance of the grounding conductor.

The protective grounding resistance must be 1 ohm and the service grounding resistance must be less than 2 ohms.

-

What are Grounding Materials?

Grounding electrodes, grounding conductors and fittings are required for the grounding system. According to the Ordinance on Grounding in Electrical Installations published by the Ministry of Energy and Natural Resources, strips, angle irons, plates and braided conductors are made as grounding elements.

These parts, which are buried in the ground and have a conductive connection with the soil, are embedded in concrete and are large surface conductors. There are two different grounding elements depending on their position.

The first of these is surface grounding.They are usually installed at a depth of 0.5 to 1 meter and can be galvanized tape, round or braided conductors. It can also be a star, eye or ring grounding or a mixture thereof.

The second grounding element is called deep grounding, which is placed vertically deeper than 1 meter. It can be made of round steel, galvanized pipe or similar profile materials.

Strip Grounding

Strip grounding consists of a round conductor or a braided conductor. It is usually not placed deep. If soil conditions are suitable, it is buried at a depth of 0.5 to 1 meter. However, at this stage, the moisture of the upper soil layer of the spreading resistance and the possibility of freezing should be taken into account.

The length is determined according to the desired spreading resistance. These longitudinally laid parts can be used as ring, star and eye grounders or as a combination of one or more of these.

Rod Earthing (Deep Earthing)

These earth rods are made of section steel and are inserted by driving them into the ground. It may be necessary to use several to achieve the desired scattering resistance with these parts, which should be driven as perpendicular to the ground as possible.

However, in this case, the distance between them should be at least twice the length of a grounding element. For reasons such as drying or freezing of the upper part of the soil, the entire length of the grounding rods connected in parallel is not effective. For this reason, care should be taken to ensure adequate spacing between them.

Plate Grounding

These parts are made of solid or perforated plates. The difference with other grounding elements is that it is buried deeper. The dimensions of these parts, which are vertically embedded in the ground, depend on the required scattering resistance. The top of the slab is laid so that it is at least 1 meter below the ground surface.

If low scattering resistance is desired, the distance between pieces should be at least 3 meters. If you want to achieve the same scattering resistance with plate grounding instead of strip or rod grounding, more parts are required.

If the ground at the grounding point is unfavorable and the resistance is not enough, a rod electrode can be reinforced at the ends of the crowbar and star grounding. Thanks to this combination, the desired result is achieved.

Crowbar Grounding

The method of burying the conductor in the ground with three feet is called crowbar grounding.

In this method, the length of the grounding conductor is 30x2 or 30x3 mm copper strip with a length of 25 m.

Things that Should be Considered When Grounding

The most important point in grounding is to ensure good contact of the electrode with the ground. If possible, the grounding element should be in contact with groundwater. However, it is not suitable to be placed directly in lake or river water.

The reason is that these waters contain few mineral salts and therefore have low conductivity. To reduce the resistance to scattering, there should be no stones or gravel around the grounding.

If possible, one of the following soil types should be selected to reduce grounding resistance:

- Moist bog soil

- Moist and wet sand

- Loam, loamy soil, clay soil, arable soil, clay soil or loam with a small percentage of sand

- Loam or clay mixed with sand in varying proportions, gravel and stones

Apart from the above soil types, dry sand, granite or very stony soils, gravelly chalk, limestone and rocks close to the ground are not suitable for grounding.

What should be Done If the Building's Grounding Conductor is Weak?

In buildings with a weak grounding wire, a cable is pulled out of a socket with a wire and this cable is connected to the copper cable or copper plate laid under the ground. If there is no plate in the underground, the cable is attached to any piece of metal in the underground.

It is important that the pulling of the grounding cable is done with great care. In order for the cable to perform its function, it must not be cut and no fuse must be connected to this cable to avoid the possibility of burns due to possible leakage. The grounding work must be performed by a professional.

What is the Grounding of Natural Gas? What are the Differences with Electrical Grounding?

If the grounding system is not done correctly, static electricity cannot discharge into the ground. However, natural gas pipes are made of steel, and if they are not protected well enough, the chimneys will rust and rot over time. With decay, natural gas or waste gas leakage also begins. Serious events such as explosion, poisoning or fire may develop due to leakage.

The gas passing through the natural gas steel pipes flows by rubbing against the inner surface of the pipe. This friction leads to the formation of static electricity in steel pipes. Static electricity occasionally jumps to other metals, and sparks can form during this jump.

If there is natural gas in the environment, the gas catches fire during the discharge of static electricity. In addition, if enough gas has accumulated, sparks can also cause fires and explosions.

For these reasons, natural gas systems that are not grounded threaten both life and property safety. Thanks to the grounding of the chimneys with the natural gas pipe, static electricity is allowed to flow into the ground. Thus, the danger is eliminated.

In terms of the purpose of construction and operation, natural gas grounding and electricity grounding are quite similar. However, there are some differences in terms of the establishment of the system.

For example, when grounding natural gas, surge arresters, also known as surge protectors, are used. However, natural gas grounding systems should be checked frequently to ensure complete safety.

Do you know if there is grounding in your home? What interests you most about grounding? You can share your thoughts with us through comments.

Online Services

Online Services Application Inquiry

Application Inquiry Pay Assurance Fee

Pay Assurance Fee Query Installation Number

Query Installation Number Compensation Fee Inquiry

Compensation Fee Inquiry Automatic Payment Order Inquiry

Automatic Payment Order Inquiry Partnership

Partnership

Leave a Comment