What is a Generator? Working Logic of Generators and Power Generation

What is in this article?

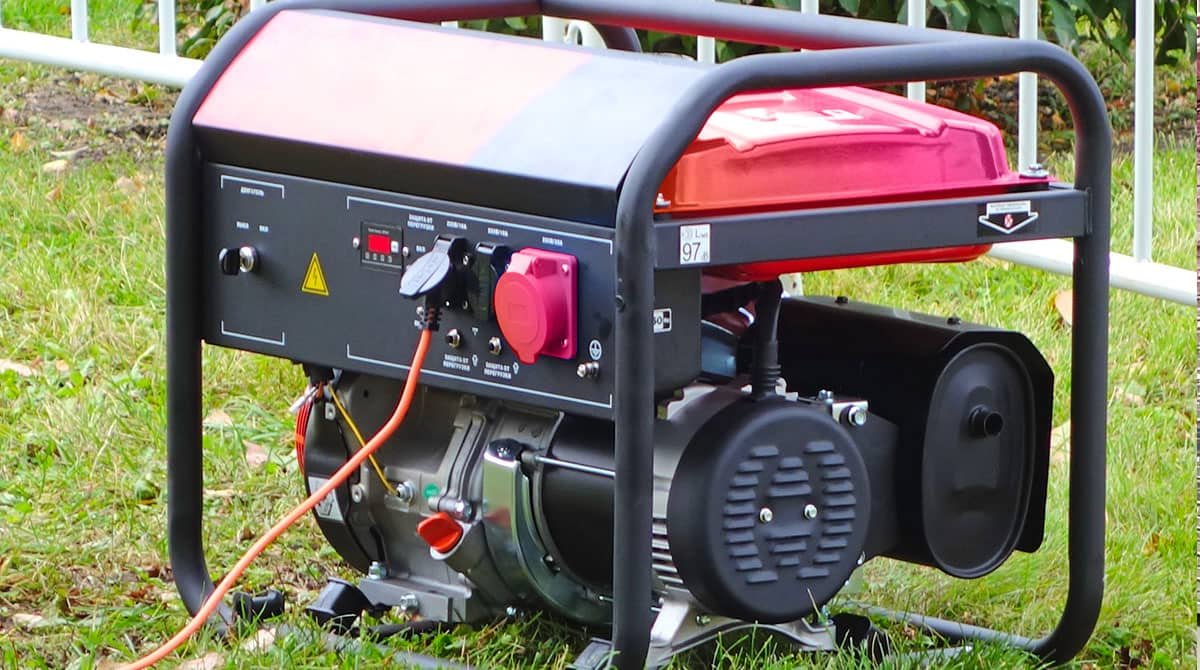

In almost every workplace and home, a constant supply of electricity is required for the reliable operation of appliances. Electricity is used for lighting, computers and electronic devices, and other systems. However, when power outages occur, generators must be used to keep equipment running.

Here you can learn how generators work, what types there are, and which generator is used in which areas.

What Is a Generator?

The generator is a device that converts kinetic energy into electrical energy. It provides electrical energy to prevent interruption of daily activities or work during a power outage. The type of fuel, power, design and characteristics of the equipment vary according to use in different areas.

How Does a Generator Work?

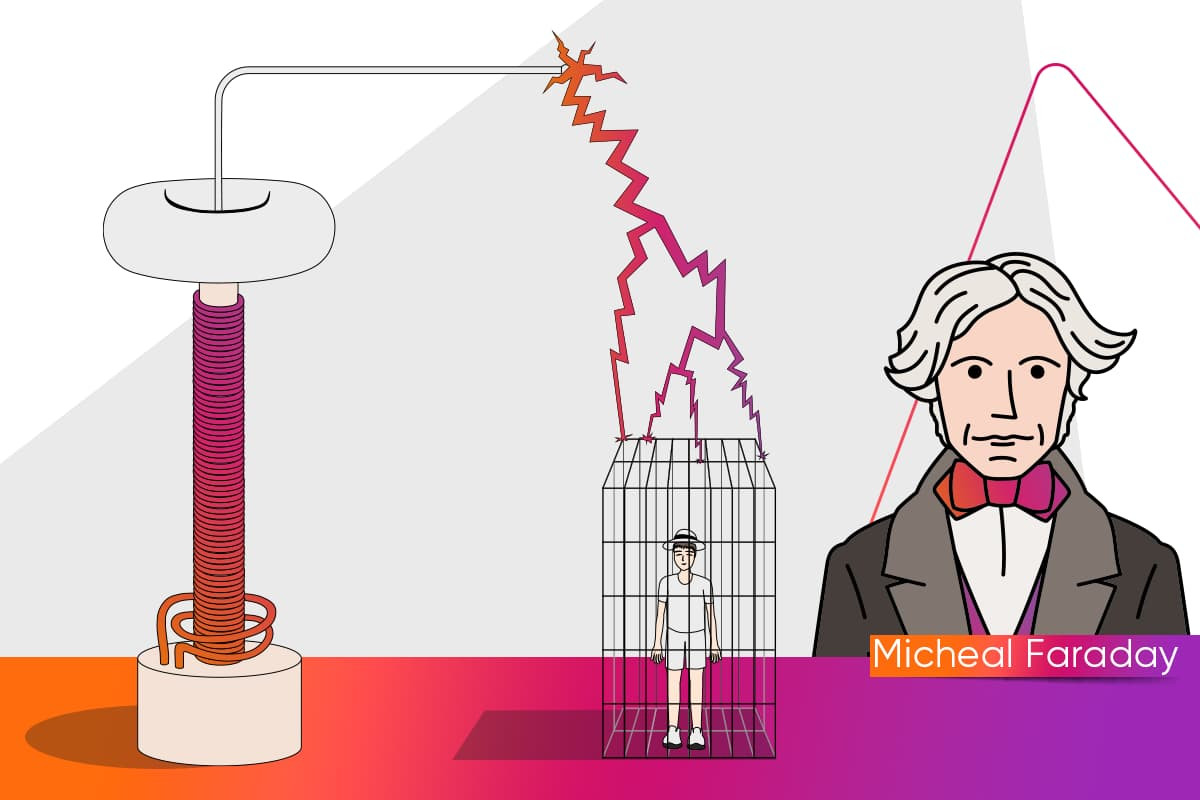

Generators, which have a similar operating principle to electric motors, require magnetic force to operate. The principle of electromagnetic induction can be explained by Faraday's law.

Generators, which have a similar operating principle to electric motors, require magnetic force to operate. The principle of electromagnetic induction can be explained by Faraday's law.

According to this law, the current in the generator depends on a rotating coil in a constant magnetic field. Current flows through the conductor due to the electromotive force (electrical action produced by a source that is not itself electrical).

There are parts that are necessary for the generation of electric current in the generator. These parts are the housing, the armature, the propeller, the coil (inductor), the covers and the brushes.

The armature with a certain number of grooves on it, is the rotating part of the generator. In these grooves, coils of copper wires are placed to generate voltage.

The coils, which form the fixed part of the generator, produce the magnetic field needed to generate power. The number of poles in the coil varies depending on the size of the equipment. In very large devices, electromagnets are used instead of permanent magnets. Propellers and cooling systems are used to prevent the generator from overheating during operation.

Conductive parts that conduct current between the magnetic poles fill the generator battery so that the electric charge and current can be transferred to electrical devices.

To generate induction current, i.e., to create current in the conducting wire, the conducting parts in the generator must move. Due to this movement, the magnetic lines change their shape and start to rotate clockwise. In this way, an induction current is created.

-

What Fuel is Used to Power the Generator?

Generators are usually powered by fossil fuels. Fossil fuels include petroleum and natural gas. Diesel is also one of the most commonly used fuels in generators.

Biodiesel and diesel-water emissions are also among the preferred fuels to reduce pollution and emissions.

When was the Generator Invented?

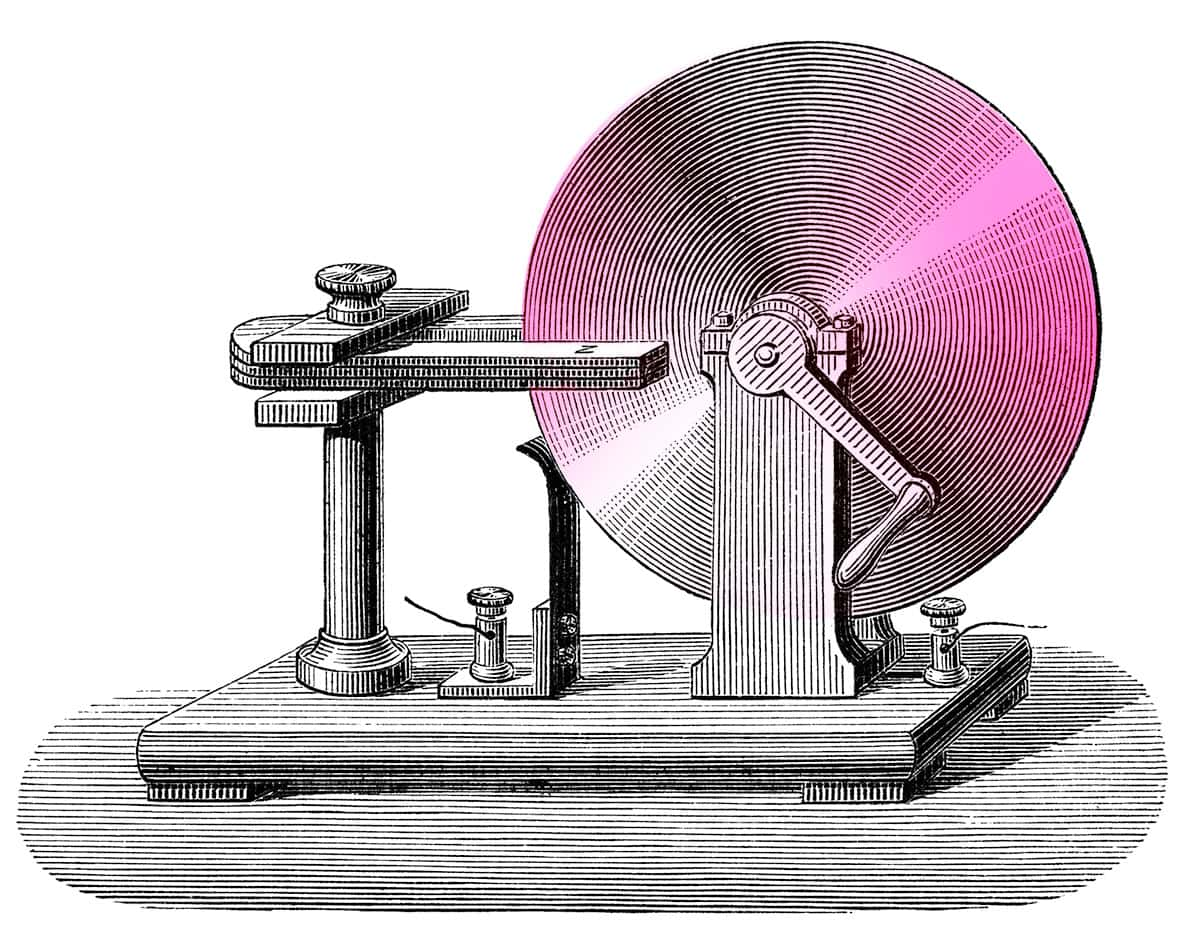

The history of the generator is as important as the history of electricity. The first prototypes of the generator used today were developed in the 1830s through the work of Michael Faraday and Joseph Henry.

The two inventors discovered and documented the phenomenon of electromagnetic induction known as Faraday's Law. Faraday also invented the first electromagnetic generator, the Faraday disk.

Following Faraday's law, in 1832French inventor Hippolyte Pixii built the first dynamo generator. This generator model he created was able to create electric pulses without current. Pixii, who coincidentally also invented the first alternator, didn't know what to do with alternating current, so he focused on eliminating alternating current to get DC power.

For the next 30 years, the battery remained the most powerful way to provide electricity, while the battery was the first electric generator capable of providing power in the industrial field.

In 1860, Antonia Pacinotti invented a dynamo that provided continuous DC power for the first time. Then Charles Wheatston and Werner Von Siemens created a more powerful and useful dynamo using a self-powered electromagnet instead of a weak permanent magnet.

In 1871, Zenobe Gramme filled the magnetic field with an iron core, which created a better path for the magnetic current. This made the power of the dynamo available for many commercial applications. After this invention, reliable and efficient dynamo designs were made by the American Charles F. Brush.

In the late 1870s, the Ganz Company began using AC generators in small commercial installations in Budapest. In 1880, Charles F. Brush operated more than 5000 arc lamps, representing 80% of the lamps worldwide.

At the International Electrotechnical Exhibition in Frankfurt in 1891, three-phase AC power proved to be the best system for power generation and distribution. Financial support from Westinghouse, Siemens, Oerlikon and General Electric increased current interest and helped improve generator design.

-

Where and What was the first Generator Used For?

The first electric generator, the Faraday generator, worked by rotating two magnets in poles around it, producing high electric current at low voltage.

The magnetic principle of this Faraday generator was widely used in the manufacture of a dynamo.

The invention of the dynamo was an important breakthrough in the electricity industry. Faraday also played an important role in the invention of electricity and electricity generation.

Many different inventions were made based on Faraday's principle. In the late 1870s, Thomas Edison introduced the electric lighting system with direct current generators. This system provided sufficient electricity for small workplaces and households.

In 1887 Nikola Tesla made significant changes in generator development by improving the existing alternating current generator. Tesla introduced the polyphase alternating current system with multiple outputs.

This invention led to the development of generators used by large companies that can produce very large amounts of electricity.

What are the Types of Generators?

Generators are generally divided into AC and DC depending on the type of current. AC generators, also called alternators, work on the principle of electromagnetic induction, that is, the movement of the magnet in a closed circuit generates electric current. In these devices, the electric current periodically changes direction. Generators are divided into asynchronous and synchronous generators.

To generate electricity, the speed of asynchronous generators, which do not need to be regulated, must be higher than the synchronous speed. So the coils rotate in a magnetic field to excite current and voltage. It runs at a steady speed for a stable AC voltage. Synchronous generators operate on the principle of simultaneous rotation.

DC generators, which run on direct current, become an uninterruptible power source for DC power grids and electrical storage devices. In these devices, the electric current flows only in one direction. The stored energy is transmitted with DC-AC converters. The advantages of DC generators include low fluctuations and low cost.

Power generators can be classified as follows, depending on the type of fuel:

-

Gasoline Generator

Gasoline generators use a gasoline engine as the power source. It generates electric current by starting the engine of the generator to interrupt the magnetic induction lines.

In addition to the gasoline engine, it consists of the rotor, the voltage regulator or capacitor, and the control panel. Due to the difference in the voltage set, a distinction is made between brushed and brushless motors.

The main advantages of the devices with compact dimensions include ease of transportation and relatively quiet operation. Thus, it can be used in various areas such as garden, warehouse, construction site.

-

Diesel Generator

Diesel generators are devices that first convert chemical energy into heat energy, then heat energy into mechanical energy, and then mechanical energy into electrical energy. For this purpose, internal combustion diesel engines are used in the generator.

The clean air filtered through the air filter mixes with the high-pressure fuel injected into the engine cylinder by the injector nozzle.

For the fuel to reach the combustion point, the temperature increases while the volume of the mixture decreases.

After the fuel is ignited, the piston is pushed down. Each cylinder pushes the piston in a specific sequence, causing the crankshaft to rotate.

This is how energy can be generated. Generators also have a combustion chamber where fuel and air are mixed.

-

Bio-Diesel Generator

Due to limited oil reserves, renewable energy sources are increasingly being used. Biodiesel is a processed fuel equivalent to diesel that is derived from biological sources.

Due to its low carbon footprint and high energy density, it is used as an alternative fuel in power generators. It increases combustion efficiency in diesel engines due to its high oxygen content. One of the advantages of biodiesel as a fuel for power generators is its low cost.

-

Emulsified Diesel Generator

Alternative fuels are used in generators to reduce emissions from diesel engines. Diesel-water emulsion is a mixture of water, diesel fuel and various additives. Since diesel fuel, which is an oil, cannot dissolve in water, the mixture can be emulsified but cannot form a homogeneous liquid.

Diesel and water emulsions can often simultaneously reducenitrous oxide (NOx) and particulate emissions from diesel engines. It also has enough potential to improve engine performance.

When water is added to the fuel mixture, the energy that the generator can produce may be reduced. The reduced capacity varies depending on the emission levels achieved, but is typically 10%-35%.

-

Propane Generator

Propane, also known as liquefied petroleum gas or LPG, is a gas that is compressed and stored as a liquid. This non-toxic gas is colorless and odorless. Today, it is used extensively for heating, but also as a fuel for vehicles and to generate power in generators.

Generators that run on propane, the liquid form of natural gas, are now widely available in compact sizes. Propane is highly flammable and releases a large amount of heat and energy when burned. This heat is used to power the generator engine and produce electrical energy.

The ammonia and water in the generator allow chemical reactions to occur. The ammonia gas produced during generator operation is vented from the unit as a gas.

Propane is characterized by its low environmental impact compared to fossil fuels. Some of the advantages of generators are that the generators require little maintenance, have high output, the fuel has no expiration date and can be used for a long time only through storage.

-

Natural Gas and Hydrogen Generators

Natural gas and hydrogen generators, which are fossil fuel generators, use natural gas and hydrogen as fuel. Natural gas is preferred because it is more affordable than diesel fuel, suitable for high fuel supply, and produces low emissions compared to other fossil fuels.

The natural gas needed to run the generator can be connected to local residential and commercial gas pipelines. Since the pipes are buried underground, the risk of deformation is low.

Also, no storage space is required as is the case with other generators. In the event of a power outage, the natural gas from the pipes ensures that the equipment will work. In this sense, uninterrupted power can be provided with unlimited resources.

-

Portable Generator

Portable generators, even if at first glance they appear to be complex devices have simple parts. They are powered by a gasoline or diesel internal combustion engine, although some models run on natural gas.

They have a fuel tank, switchboards, an alternator, safety systems, and a body.

The engine drives the alternator with the fuel in the tank providing combustion energy. The alternator, which consists of a shaft connected to the engine, turns the electromagnets in the coil to create an electric field.

This current is converted into voltage through the regulator and transmitted to the devices to which the generator is connected.

What Parts are Included in the Generator Structure?

A generator consists of auxiliary parts such as fuel tank, exhaust, transmission lines, chassis and cooling systems besides the engine and alternator, which are the basic parts.

-

Engine

Every machine usually contains an engine that converts the fuel source into usable energy and allows it to move or perform its mechanical function. The engines in generators also use a fuel source such as gasoline, diesel, natural gas, propane, biodiesel, etc., to produce the mechanical energy that converts the device into electricity.

The design of any generator engine aims to maximize electrical current by operating on a specific fuel or other energy source. Engines commonly used in generator design include reciprocating engines, steam engines, turbine engines, and microturbines.

-

Alternator

The alternator is the part that delivers the power of the generator. Despite its complex structure, which consists of many different components, the most important part of the alternator is the rotor. The rotor is a shaft with a large number of permanent magnets fixed around it, which rotate with the mechanical energy provided by the engine. In the process, it generates a magnetic field.

This generated magnetic field continuously rotates around the stator, another important part of the alternator. According to the principle of electromagnetic induction, an electric current is induced when an electrical conductor is stationary and a magnetic field moves around it.

In this sense, the alternator induces the rotor to produce a magnetic field that moves around the stator. It absorbs the mechanical energy generated by the diesel engine to produce an alternating current.

-

Fuel Tank

Fuel-powered generators have a system that stores and pumps the appropriate fuel to the engine. The tank contains enough fuel to run a generator. The fuel line connects the tank to the engine, while the return line connects the engine to the fuel tank to return the fuel.

A fuel pump delivers fuel from the tank to the fuel line and to the engine. A fuel filter removes all impurities from the fuel before it is delivered to the engine. The fuel injector sprays fuel directly into the engine's combustion chamber.

-

Regulator

The regulator, which is used to control the output voltage, is one of the most complex parts of the generator. It ensures that the generator produces power at a constant voltage.

Without this part, there may be large fluctuations depending on the operating speed of the engine. Power tools may not work if the power supply is unstable. A regulator is required to keep the voltage stable and to operate the equipment.

-

Control Panel

The control panel is the part from which the generator is controlled and operated. There are a number of buttons on the control panel that can be used to make various adjustments and check certain numbers.

The start button, frequency switch, fuel gauge, coolant temperature gauge and more are located on the control panel.

-

Cooling and Exhaust Systems

The continuous operation of the generator will cause the working parts to heat up. The cooling system is an integral part of any generator to regulate the temperature and prevent overheating. Most generators have an air-cooled or liquid-cooled system to regulate internal heat.

Air-cooled generator systems lower the temperature of the mold by drawing air from the atmosphere and blowing it into the generator. An advantage of this type of cooling system is that no coolant pump or connecting hoses are required. Because of the simplicity of an air-cooled system, less maintenance is also required, but air-cooled generators can overheat during extended operation. This can lead to breakdowns and irreparable damage.

Liquid cooling systems use coolant or oil in combination with a radiator and water pump to regulate the internal temperature of a generator. The pump has a network of hoses to deliver the coolant to the engine.

The fluid absorbs heat and transfers it to the radiator to cool the air. Operating costs for these cooling systems can be higher. Because they are more complex systems, they often require more attention and maintenance.

Generators produce vapors that contain hazardous chemicals. Certain parts are needed to exhaust these vapors. Exhaust systems discharge the fumes generated during operation through a pipe that leads away from high-traffic areas.

How Does the Generator Turn on When the Power is Turned off?

The automatic transfer switch in generators allows the generator to be connected to the electrical system in the home or workplace. Most generators automatically select power during a power outage.

When the generator detects a power failure, it automatically starts the engine and switches on the power generation unit, the alternator. The alternator converts the mechanical energy of the combustion engine into electrical energy.

After a few seconds, during which the engine speed and electrical power stabilize, the switch disconnects the home from the power grid and supplies power to the home or workplace. When power is restored, the transfer switch turns off the generator. The generator runs for a short time and then shuts down.

-

How Long does it Take for the Generator to Restart When It is Shut off?

Depending on the model of the generator and the control unit settings, the equipment will turn on in less than 30 seconds after the power outage begins.

5 Points to Consider When Using a Generator

Some of the things to watch out for when using the generator are the following:

-

Keep the Generator Away from Living Areas

Operating the generator in or too close to a living area can cause burns from contact with a hot appliance and death or injury from carbon monoxide (CO) poisoning. The generator's engine exhaust, which should not be located near homes or workplaces, should also not be located near windows and doors.

-

Keep Portable Generator Away From Liquids

Portable generators should not be operated in the rain. Sheltered and well-ventilated awnings can be used for generators used outdoors.

-

Pay Attention to Fuel Consumption

A gas-powered generator must be turned off and cooled before refueling. Gasoline poured into a hot engine can ignite. Allowing the engine to cool also reduces the risk of burns when refueling.

-

Storing Fuel

In the event that the generator must be operated for an extended period of time, it is important to obtain an additional supply of fuel and store it properly. Fuel should only be stored in an approved container in a well-ventilated and cool environment. It is also important that it is not stored near a possible heat or fire source or indoors.

-

Use Transfer Switch

In order for the generator to power electrical appliances, it must be connected to the appliances via a transfer switch. The transfer switch connects the generator to the circuit panel and transfers power to wired appliances.

It also avoids the safety risk of using extension cords. Most transfer switches also help prevent overloading by providing a display of the electrical power drawn from the grid.

Which Generator to Use for Homes?

Homes usually use portable generators, which are easy to carry around.

Homes usually use portable generators, which are easy to carry around.

These appliances come to the rescue when mains electricity is temporarily unavailable.

The power of the models can be determined according to the electrical appliances to be used.

In the event of prolonged outages, it is important that lighting products as well as white goods such as refrigerators, freezers and electronic devices such as televisions and computers continue to operate.

Low-capacity generators may be sufficient for a few electrical appliances that need to run continuously at home.

n this case, it is useful to calculate the total power draw of the devices and choose the smallest portable generator that will meet this power.

Although the operating power of household appliances varies depending on the model and size, below are some average values:

- Water heater: 1500W-2000W

- Incandescent bulbs: 60W-100W

- LED bulbs: 8W-12W

- Hair dryer: 1500W-2500W

- Laptop: 50W-200W

- Smartphone charger: 5W-15W

- Air Conditioner: 1000W-4000W

- Refrigerator and freezer: 150W-600W

- Toaster: 800W-1800W

- Microwave: 700W-1800W

You can share your experiences about the generators you use in your home or workplace in the comments.

Online Services

Online Services Application Inquiry

Application Inquiry Pay Assurance Fee

Pay Assurance Fee Query Installation Number

Query Installation Number Compensation Fee Inquiry

Compensation Fee Inquiry Automatic Payment Order Inquiry

Automatic Payment Order Inquiry Partnership

Partnership

Leave a Comment

Comments (1)

A

Alican inan

3.5 lik bir jenarator ile evimin ihtiyacını karşılamam da her ha gi nir yasal sumlu tutulur mu