What Exactly Is Industry 4.0? How Does It Impact the Energy Sector?

What is in this article?

The evolution of technology has been reshaping the industrial world at its core, and Industry 4.0 represents the latest phase in this transformation. Yet, this revolution goes beyond just altering production processes; it also has profound implications for the energy industry.

Picture this: electricity companies analyzing real-time energy demands to drastically reduce waste. At such a juncture, Industry 4.0 is hailed as the biggest leap in digitalization, incorporating cutting-edge technologies like smart production systems, the Internet of Things, and artificial intelligence.

In our article, we’ll dive deep into what Industry 4.0 really means, how it differs from previous industrial phases, and its significant effects on energy efficiency.

What Exactly Is Industry 4.0?

The 4.0 Industrial Revolution, born from blending digital technologies with traditional manufacturing, is all about smart production systems in factories and other industrial settings. To put it simply, this revolution is pushing the manufacturing sector towards a more digitalized future, making it easier to integrate automation processes.

It's fundamentally about bringing together technologies like automation, the Internet of Things, big data analysis, and artificial intelligence. This integration boosts machine-to-machine communication, ramps up efficiency, and brings unparalleled flexibility to production processes.

Want to get a better grasp on the industry's evolution and IoT, a cornerstone of the 4.0 Industrial Revolution? Check out our detailed article, Understanding the Internet of Things: How It Works.

Industry 4.0 empowers facilities to self-optimize and ramp up their production efficiency. It leverages data gathered by sensors, processed in real-time, to reduce mistakes and sharpen decision-making. In essence, sensors and data analytics play a crucial role in diminishing production errors, thereby refining management and production workflows. Moreover, it allows for unprecedented customization in production processes. This, in turn, significantly boosts the ability to offer highly tailored products and services to customers.

At its heart, the main aim of Industry 4.0 is to create smarter, more efficient, and adaptable production processes. Industry 4.0 enables gaining a competitive advantage by making the best use of today's technological capabilities. Moreover, it creates profound effects not only in production but also in the energy sector.

What Are the Differences Between Industry 4.0 and 3.0?

The differences between Industry 4.0 and 3.0 mark a significant milestone in the digital advancements of the production world. This transformation aims to bring more intelligence, efficiency, and flexibility to industrial processes.

The developed features, ranging from improved machine communication to enhanced data analytics capabilities, distinguish it from previous industrial stages. The primary reason for the prominence of Industry 4.0 lies in its significant innovations compared to earlier industrial stages. While Industry 3.0 automated production processes, Industry 4.0 represents a major leap in digitalization.

| Criteria | Industry 3.0 | Industry 4.0 |

|

Communication - Connection |

Communication between machines is often limited, using centralized control systems. | The Internet of Things (IoT) allows for strong/instant communication between machines, increasing data sharing and enabling faster decision-making. |

| Data Usage - Analytics | Data is usually collected in limited ways and often analyzed manually. | Big data analytics and real-time data processing capabilities enable the use of large amounts of data. This facilitates relatively smarter decision-making in management and production. |

| Autonomy - Automation | Automation exists but is typically limited to specific functions. | Machines become more autonomous. Artificial intelligence enhances the ability of learning machines to perform complex tasks |

| Flexibility - Customization | There is usually a focus on standard production processes, making it difficult to adapt to changes. | It offers flexible production processes, allowing for rapid adaptation to orders and the production of customized products. |

What Technologies and Principles Does Industry 4.0 Incorporate?

Industry 4.0, bringing digital transformation to production processes, is based on a series of technologies and fundamental principles. The integration of these technologies will be key in shaping future industrial transformation. IoT, for example, is one of the foremost technologies. IoT, a cornerstone of Industry 4.0, enables machines/devices to communicate with each other. Data collection/sharing through sensors facilitates effective management of production processes.

Other technologies driving the 4.0 industrial revolution include:

- Big data analytics, enabling meaningful insights from large data sets. The analysis of data in production processes is used to reduce errors, increase efficiency, and make accurate decisions.

- AI and machine learning enable machines to learn from data and make decisions. They help in effectively and efficiently managing complex tasks in production processes.

- Robot technology and automation are key players in Industry 4.0. They ramp up production speeds and accuracy by cutting down on the need for human input.

- Vertical integration links up production processes, while horizontal integration fuses different functional areas. These integrations streamline industrial operations, making them more coordinated and efficient.

- VR and AR find their way into numerous fields, from training to maintenance. In production, they bring benefits like better training for workers, streamlined maintenance, and enhanced design phases.

What Does It Take To Shift From Old Systems to Industry 4.0?

Moving to Industry 4.0 marks a critical step from traditional to flexible, intelligent production systems. This shift, however, comes with its share of complexities. It involves integrating a slew of technologies, from digital infrastructure and IoT to big data management and AI/machine learning. So, this shift isn't just about tech upgrades; it's also about transforming the organizational culture.

Key steps for embracing Industry 4.0 include:

- Digitalizing traditional system equipment and integrating IoT sensors for seamless data sharing and machine communication.

- Making the shift requires managing large data volumes effectively. Robust infrastructure for data storage, analysis, and security is a must.

- Core AI and machine learning applications need to be woven into production for smarter decision-making and boosted efficiency.

- The 4.0 revolution paves the way for an automated, tech-driven work environment. Hence, rolling out training programs to upskill employees in digital tech and ease their tech adaptation is essential.

- As we embrace digitalization, the associated security risks also climb. It's essential to craft a comprehensive security strategy to safeguard systems and data.

- Shifting from old systems to Industry 4.0 requires ensuring different devices and systems can work together seamlessly, adhering to integration and communication standards.Given the significant change this transition represents, it's crucial to test new technologies and processes through pilot projects, followed by necessary improvements.

What's Industry 4.0's Impact in the Energy Sector?

Industry 4.0, used to drive fundamental transformation and boost efficiency, plays a massive role in the energy sector.

Industry 4.0, used to drive fundamental transformation and boost efficiency, plays a massive role in the energy sector.

Integrating smart metering devices and sensors elevates the data collection process in energy facilities. This leads to better insights into production variables and sharper demand forecasting.

Plus, improved communication between devices in energy facilities enables better energy flow management, leading to more efficient use of resources. These tech advancements are pivotal in developing a sustainable, optimized energy infrastructure.

The reliability and resilience of the energy sector are also enhanced. Thanks to Industry 4.0, smart grids can swiftly detect issues using real-time data, reducing energy downtime.

Energy storage technologies also play a part, efficiently storing energy from renewable sources to ensure a steady supply. In essence, Industry 4.0 in the energy sector steps towards a sustainable future by minimizing environmental impacts and smarter energy use.

-

How Does Industry 4.0 Contribute to Innovations in Energy?

One of the standout contributions of Industry 4.0 in energy is the development of smart grids and measurement systems. It fosters a radical transformation in the energy sector, paving the way for a sustainable energy future through the lens of Energy 4.0. Another key role it plays is facilitating effective communication between energy facilities.

Thanks to the Internet of Things (IoT), energy producers can access real-time data for optimizing demand forecasts and regulating energy flow. This transformation paves the way for the energy sector to evolve into a more flexible and efficient version of itself.

Related Article

What are Renewable Energy Sources?

How Does Industry 4.0 Impact Energy Efficiency?

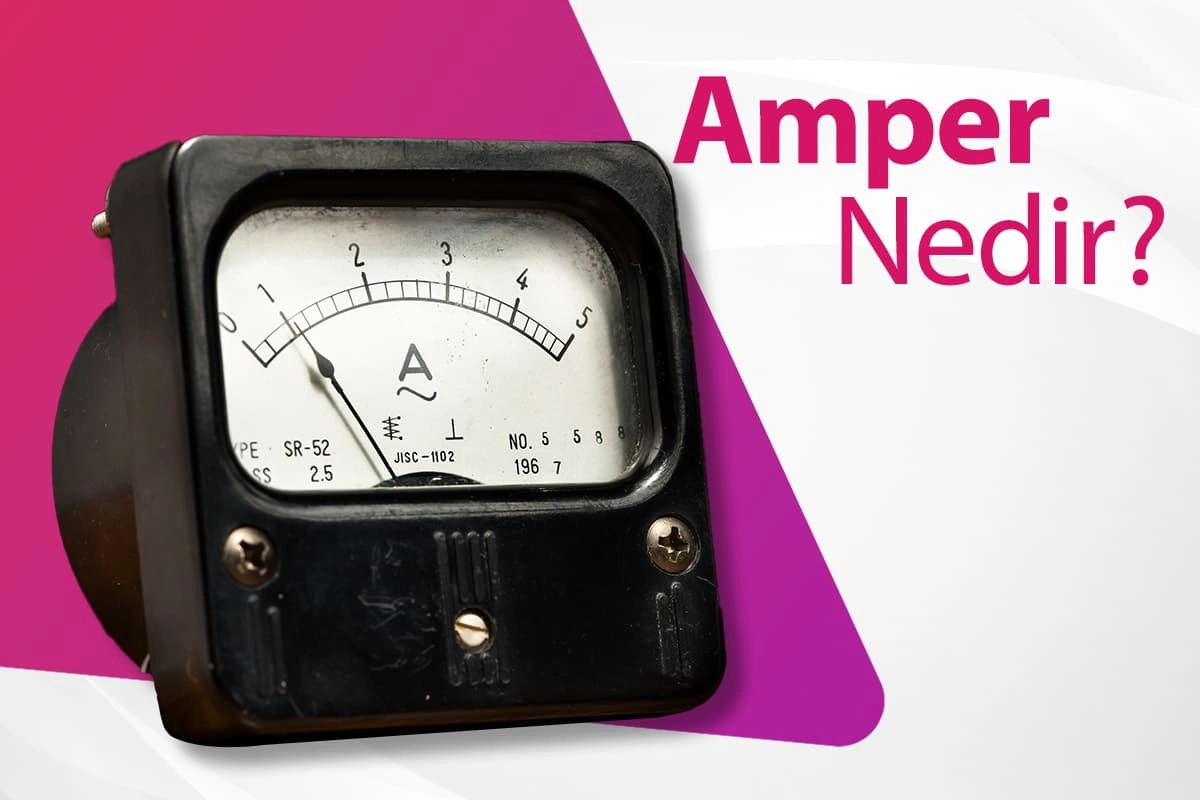

The influence of the 4.0 Industrial Revolution on energy efficiency comes through by offering a smarter and more dynamic approach compared to traditional energy management systems. The integration of smart metering devices and sensors enables real-time monitoring of energy consumption. The data collected are used to enhance the efficiency of operations in energy facilities and, more importantly, to minimize unnecessary energy waste.

As digital transformation aims to make production processes smarter and more efficient, technologies like LoRaWAN, a long-range wireless communication technology, come into play. This technology contributes to the vision of Industry 4.0 by enabling data collection, remote monitoring, and control in industrial facilities. LoRaWAN stands out as a long-range, wide-area network-based wireless communication protocol. In the 4.0 Industrial Revolution, especially through Internet of Things (IoT) applications, this technology plays a vital role by enhancing industrial processes and making them smarter, more efficient, and deeply interconnected.

Related Article

What Is LoRaWAN? What Are Its Advantages?

How Do Energy Companies Embrace and Implement Industry 4.0?

Energy companies can gain numerous advantages by adopting Industry 4.0. For instance, the use of smart meters can be expanded. By offering smart meter systems to customers, energy companies enable real-time monitoring of consumption data. This not only provides detailed insights into energy usage patterns but also aids in better understanding customer demands. Moreover, smart meters enable quicker and more effective error detection.

The real-time monitoring feature gives energy companies the ability to understand consumption habits and offer tailored energy-saving recommendations to their customers. This approach yields detailed information about customers' energy usage habits and leads to a better understanding of energy demands. Furthermore, the data provided by smart meters enable energy companies to plan more effectively and optimize energy distribution. All these are turbocharging Industry 4.0's makeover of the energy sector.

The real-time monitoring feature gives energy companies the ability to understand consumption habits and offer tailored energy-saving recommendations to their customers. This approach yields detailed information about customers' energy usage habits and leads to a better understanding of energy demands. Furthermore, the data provided by smart meters enable energy companies to plan more effectively and optimize energy distribution. All these are turbocharging Industry 4.0's makeover of the energy sector.

Take, for instance, the smart makeover of building management for energy efficiency. Smart building systems are game-changers, offering energy companies critical data to fine-tune energy use in buildings, making every watt count. This means heating, cooling, and lighting aren't just on or off; they're smartly managed for optimal comfort and efficiency.

Then there are the smart sensors in power lines – real-time watchdogs giving energy companies a live feed of the line's health and performance. Predicting power outages and fine-tuning maintenance turn into smooth operations, sidestepping those unexpected blackout curveballs.

Thanks advanced data analytics and control prowess that comes with Industry 4.0, energy companies are hitting the mark in seamlessly weaving renewables like solar panels and wind turbines into the energy mix. And let's not forget smart storage systems – they're like the brainy balancers of energy demands, keeping the energy flow smooth and steady.

The innovations Industry 4.0 is ushering into the energy sector – smart, sustainable, future-forward – are nothing short of revolutionary. Energy companies, riding the wave of this tech evolution, are at the brink of crafting energy systems that are not just powerful but also planet-friendly.

What's your take on Industry 4.0 stirring up the energy efficiency and sustainability scene? Do you think it's got the chops to help us take on global warming's tough challenges? Drop your insights.

Online Services

Online Services Application Inquiry

Application Inquiry Pay Assurance Fee

Pay Assurance Fee Query Installation Number

Query Installation Number Compensation Fee Inquiry

Compensation Fee Inquiry Automatic Payment Order Inquiry

Automatic Payment Order Inquiry Partnership

Partnership

Leave a Comment